OUR PROCESS

Since 2005, we have built and maintained strong partnerships with our suppliers to ensure the production of the highest quality turbochargers. Backed by over 40 years of combined expertise, our experienced team of application and manufacturing engineers excels in engineering, design, inspection, and testing.

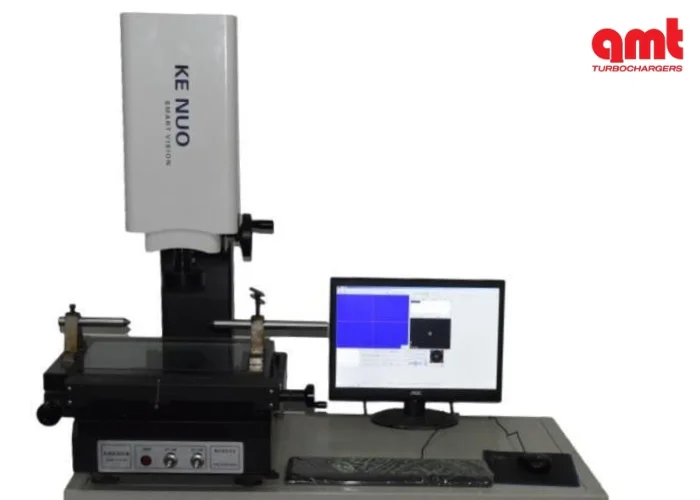

To uphold our rigorous standards, our production engineers conduct regular inspections and precise measurements of incoming parts, swiftly addressing any potential defects to guarantee superior quality. This meticulous attention to detail ensures that every turbocharger we produce meets or exceeds customer expectations for performance and reliability. We deliver turbochargers you can trust.

OUR BUSINESS APPROACH & PHILOSOPHY

To develop the highest quality assured turbochargers, AMT Turbochargers combines exceptional expertise with a “POWER TO” philosophy. This approach fosters collaboration and dedication, driven by a quality-focused vision that ensures excellence at every step.

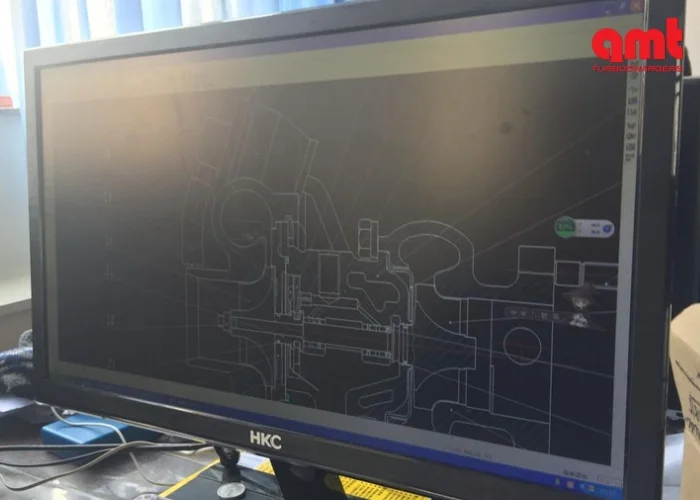

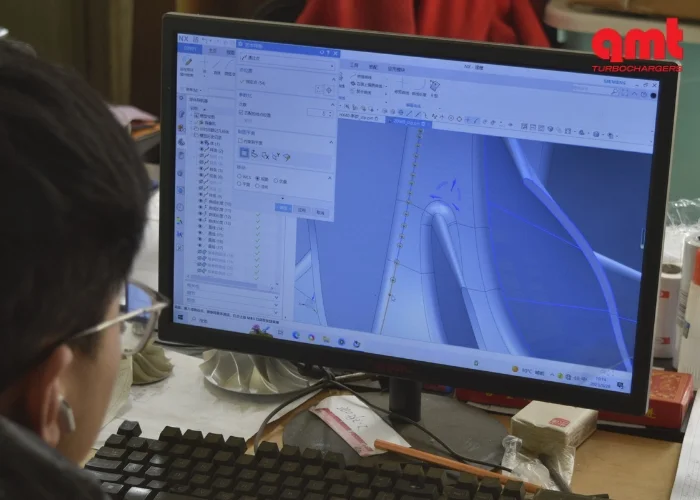

REVERSE ENGINEERING & DESIGN

POWER OF EXPERIENCE

At AMT Turbochargers, we reverse-engineer, design, and manufacture our turbo parts and turbochargers to meet original equipment (OE) specifications. Our facility in Jiangsu Province, China is equipped with the latest reverse engineering equipment and design software packages.

Our vertically integrated communication system facilitates direct feedback from the field, enabling us to share information with our design and manufacturing engineers. This system allows us to identify design flaws in original products and provide solutions that enhance the durability and performance of our turbochargers, parts, and components.

MANUFACTURING

POWER OF PRECISION

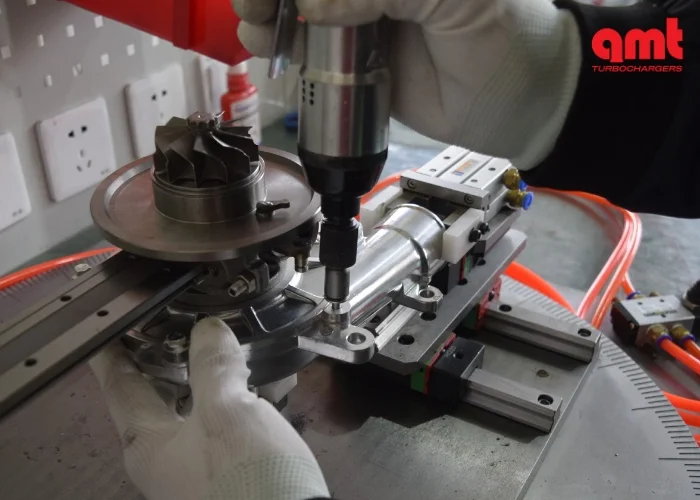

Since 2005, AMT Turbochargers has built and nurtured strong partnerships between our team of skilled engineers and the engineers of our trusted suppliers. These collaborations are the foundation of our ability to deliver products that consistently meet and exceed industry standards.

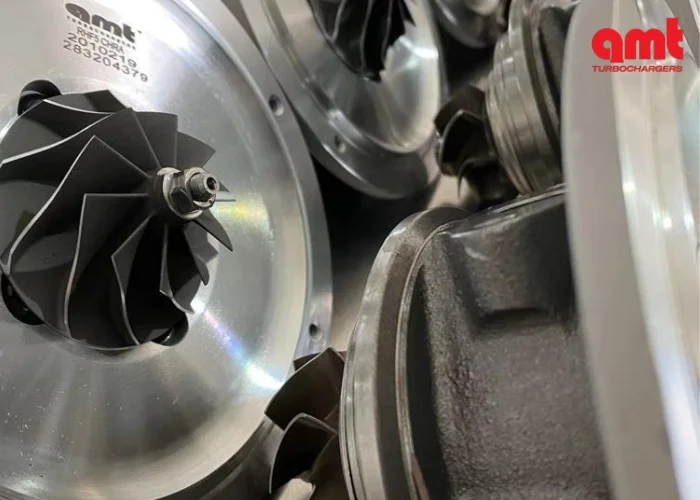

Central to our commitment to quality is our proprietary SuperTrace quality control platform. This advanced system ensures meticulous management of critical materials, including Molybdenum and SiMo+ alloys for turbine housings, as well as Inconel 713 for turbine wheels, materials known for their exceptional strength and heat resistance.

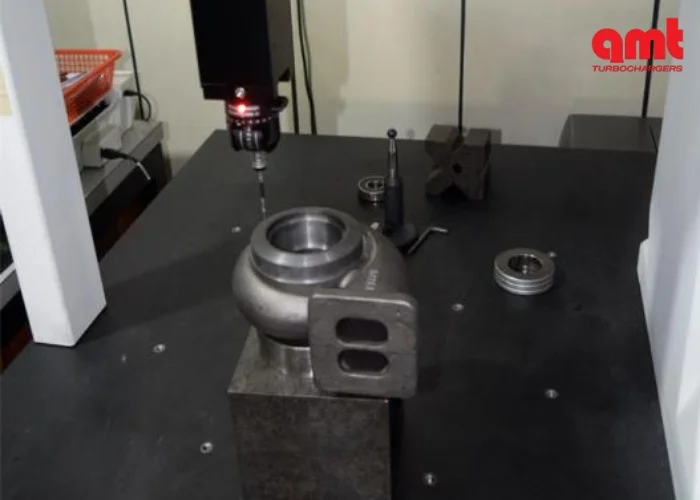

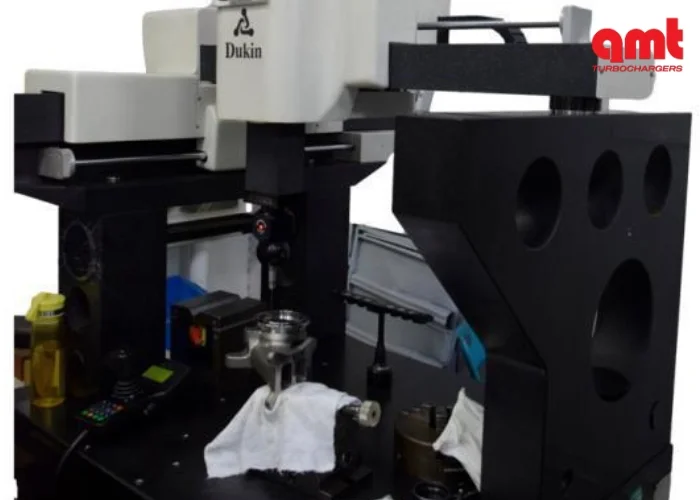

QUALITY ASSURANCE

POWER OF ANALYSIS

Quality is our top priority, starting with the meticulous selection of input materials. Our input material analysts uphold strict zero-tolerance standards to ensure that only the highest-quality components are used in our products.

This commitment is reinforced by our proprietary SuperTrace quality assurance platform, which oversees every aspect of our material testing and approval processes. We conduct rigorous tolerance and material conformity tests on all input materials.

Through critical tolerance management and compatibility testing, we guarantee that our turbo components are fully interchangeable with original parts.

ASSEMBLY & TESTING

POWER OF PERCEPTION

Our assembly line operates with the greatest of precision, guided by our proprietary SuperTrace quality assurance platform. This system cross-checks input materials during the assembly process against stringent QC standards, ensuring consistent quality at every step.

To further enhance quality, we incentivise our assembly team through a reward system that recognises their commitment to excellence.

We offer an extensive range of 50,000 CHRA, covering more than 12,000 turbocharger references and over 1,000-part numbers, providing reliable solutions for a wide variety of applications.